Browse

Keywords

Records with Keyword: Steam Reforming

Thermodynamic Analysis of Hydrogen Production from Bio-Oil Steam Reforming Utilizing Waste Heat of Steel Slag

September 20, 2023 (v1)

Subject: Energy Systems

Keywords: bio-oil, heat recovery, Steam Reforming, steel slag, thermodynamic analysis

(1) Background: The discharged temperature of steel slag is up to 1450 °C, representing heat having a high calorific value. (2) Motivation: A novel technology, integrating bio-oil steam reforming with waste heat recovery from steel slag for hydrogen production, is proposed, and it is demonstrated to be an outstanding method via thermodynamic calculation. (3) Methods: The equilibrium productions of bio-oil steam reforming in steel slag under different temperatures and S/C ratios (the mole ratio of steam to carbon) are obtained by the method of minimizing the Gibbs free energy using HSC 6.0. (4) Conclusions: The hydrogen yield increases first and then decreases with the increasing temperature, but it increases with the increasing S/C. Considering equilibrium calculation and actual application, the optimal temperature and S/C are 706 °C and 6, respectively. The hydrogen yield and hydrogen component are 109.13 mol/kg and 70.21%, respectively, and the carbon yield is only 0.08 mol/kg under... [more]

Hydrogen Production by Steam Reforming of Pyrolysis Oil from Waste Plastic over 3 wt.% Ni/Ce-Zr-Mg/Al2O3 Catalyst

April 18, 2023 (v1)

Subject: Energy Systems

Keywords: Hydrogen, Ni catalyst, oil pyrolysis, Steam Reforming, waste plastic

Sustained increase in plastic use has placed a significant burden on waste disposal infrastructure. Pyrolysis is the process of decomposing high-molecular-weight compounds by heating waste plastics at 500−1000 °C without oxygen. This process considerably reduces greenhouse gas emissions and has a high alternative energy effect (0.57 TOE ton−1). After a separation process, the oil produced by pyrolysis (C5−C20) can yield naphtha oil (C6−C7). Subsequently, hydrogen can be produced through a reforming reaction of this naphtha oil. Here, we produced hydrogen from waste plastic pyrolysis oil over a Ni/Ce-Zr-Mg/Al2O3 catalyst using a steam reforming process. A model oil combining the major substances of C6 and C7 (hexane, hexene, heptane, heptene, and toluene) was formed. From the reaction products, the hydrogen yield was obtained based on analysis of H2, CO, and CO2 concentrations using gas chromatography. The effect of N2 and O2 addition on hydrogen yield was analyzed within a temperature... [more]

Catalytic Hot Gas Cleanup of Biomass Gasification Producer Gas via Steam Reforming Using Nickel-Supported Clay Minerals

April 14, 2023 (v1)

Subject: Energy Systems

Keywords: biomass gasification, clay, nickel montmorillonite, Steam Reforming, tar removal/conversion

Amongst the issues associated with the commercialization of biomass gasification, the presence of tars has been one of the most difficult aspects to address. Tars are an impurity generated from the gasifier and upon their condensation cause problems in downstream equipment including plugging, blockages, corrosion, and major catalyst deactivation. These problems lead to losses of efficiency as well as potential maintenance issues resulting from damaged processing units. Therefore, the removal of tars is necessary in order for the effective operation of a biomass gasification facility for the production of high-value fuel gas. The catalytic activity of montmorillonite and montmorillonite-supported nickel as tar removal catalysts will be investigated in this study. Ni-montmorillonite catalyst was prepared, characterized, and tested in a laboratory-scale reactor for its efficiency in reforming tars using naphthalene as a tar model compound. Efficacy of montmorillonite-supported nickel cata... [more]

A Thermodynamic Analysis of Heavy Hydrocarbons Reforming for Solid Oxide Fuel Cell Application as a Part of Hybrid Energy Systems

April 12, 2023 (v1)

Subject: Energy Systems

Keywords: Associated Petroleum Gas, equilibrium characteristics, parametric equation formalism, Solid Oxide Fuel Cells, Steam Reforming

A thermodynamical analysis of steam reforming of Associated Petroleum Gas (APG) was conducted in the presented research. The reforming process of heavy hydrocarbons for small scale power generation is a complex issue. One of the main issues is that a set of undesired chemical reactions deposit solid carbon and, consequently, block the reactor’s catalytic property. The experimental investigation is crucial to design an APG reforming reactor. However, a numerical simulation is a key tool to design a safe operating condition. Designing the next generation of reactors requires a complex coupling of mathematical models, kinetics, and thermodynamic analysis. In practice, the thermodynamic analysis should be applied in each control volume to assure realistic results. This is not easy to apply in practice since both thermodynamic analysis and CFD modeling can be time-consuming. In this paper, the authors suggest using a mathematical formalism called Parametric Equation Formalism to calculate t... [more]

Co-Gasification of Crude Glycerol/Animal Fat Mixtures

March 24, 2023 (v1)

Subject: Energy Systems

Keywords: animal fat, co-gasification, crude glycerol, fixed-bed, Steam Reforming

The aim of this work was to assess the technical viability of glycerol/fat co-gasification. The gasification performance was studied in a downflow fixed bed reactor using activated alumina particles as bed material and steam as oxidizing agent. The effect of gasification temperature, from 800 to 950 °C was studied with a feed mixture with 10% (w/w) of animal fat. The influence of fat incorporation on the feedstock in the overall gasification process was also performed, using 3% (w/w) and 5% (w/w) of fat in feed mixtures. Samples of dry gas from the gasifier were collected and analyzed by gas chromatography in order to determine the CO, CO2, CH4, and H2 content. The best results were obtained using the highest tested temperature, 950 °C, and using 3% (w/w) of animal fat in the feed mixture. The overall results revealed that the co-gasification of glycerol/animal fat mixtures seems to be a feasible technical option.

Catalytic Steam Reforming of Toluene: Understanding the Influence of the Main Reaction Parameters over a Reference Catalyst

March 22, 2023 (v1)

Subject: Energy Systems

Keywords: coke formation, GHSV, S/C ratio, Steam Reforming, Toluene

Identifying the suitable reaction conditions is key to achieve high performance and economic efficiency in any catalytic process. In this study, the catalytic performance of a Ni/Al2O3 catalyst, a benchmark system—was investigated in steam reforming of toluene as a biomass gasification tar model compound to explore the effect of reforming temperature, steam to carbon (S/C) ratio and residence time on toluene conversion and gas products. An S/C molar ratio range from one to three and temperature range from 700 to 900 °C was selected according to thermodynamic equilibrium calculations, and gas hourly space velocity (GHSV) was varied from 30,600 to 122,400 h−1 based on previous work. The results suggest that 800 °C, GHSV 61,200 h−1 and S/C ratio 3 provide favourable operating conditions for steam reforming of toluene in order to get high toluene conversion and hydrogen productivity, achieving a toluene to gas conversion of 94% and H2 production of 13 mol/mol toluene.

Biomass Potential for Producing Power via Green Hydrogen

March 3, 2023 (v1)

Subject: Energy Systems

Keywords: bioethanol, catalyst, Fuel Cells, Steam Reforming, steam-to-ethanol ratio

Hydrogen (H2) has become an important energy vector for mitigating the effects of climate change since it can be obtained from renewable sources and can be fed to fuel cells for producing power. Bioethanol can become a green H2 source via Ethanol Steam Reforming (ESR) but several variables influence the power production in the fuel cell. Herein, we explored and optimized the main variables that affect this power production. The process includes biomass fermentation, bioethanol purification, H2 production via ESR, syngas cleaning by a CO-removal reactor, and power production in a high temperature proton exchange membrane fuel cell (HT-PEMFC). Among the explored variables, the steam-to-ethanol molar ratio (S/E) employed in the ESR has the strongest influence on power production, process efficiency, and energy consumption. This effect is followed by other variables such as the inlet ethanol concentration and the ESR temperature. Although the CO-removal reactor did not show a significant e... [more]

Mathematical Model of Steam Reforming in the Anode Channel of a Molten Carbonate Fuel Cell

March 3, 2023 (v1)

Subject: Energy Systems

Keywords: MCFC, molten carbonate fuel cell, Steam Reforming

The paper presents a mathematical model of a molten carbonate fuel cell with a catalyst in the anode channel. The modeled system is fueled by methane. The system includes a model of the steam reforming process occurring in the anode channel of the MCFC fuel cell and the model of the cell itself. A reduced order model was used to describe the operation of the molten carbonate fuel cell, whereas a kinetic model describes the methane steam reforming. The calculations of the reforming were done in Aspen HYSYS software. Four values of the steam-to-carbon ratio (2.0, 2.5, 3.0, and 3.5) were used to analyze the performance of the reforming process. In the first phase, the reaction kinetics model was based on data from the literature.

System Simulation and Analysis of an LNG-Fueled SOFC System Using Additively Manufactured High Temperature Heat Exchangers

March 2, 2023 (v1)

Subject: Modelling and Simulations

Keywords: additively manufactured heat exchangers, anode off-gas recirculation, fuel cell system design, maritime application, solid oxide fuel cell, Steam Reforming

A laboratory-scale solid oxide fuel cell (SOFC) system using liquefied natural gas (LNG) as a fuel is designed to be used as an energy converter on seagoing vessels (MultiSchIBZ project). The presented system design phase is supported by thermodynamic system simulation. As heat integration plays a crucial role with regard to fuel recirculation and endothermic pre-reforming, the heat exchanger and pre-reforming component models need to exhibit a high degree of accuracy throughout the entire operating range. Compact additively manufactured tube-bundle and plate-fin heat exchangers are designed to achieve high heat exchange efficiencies at low pressure losses. Their heat transfer correlations are derived from experimental component tests under operating conditions. A simulation study utilizing these heat exchanger characteristics is carried out for four configuration variants of pre-reforming and heat integration. Their system behaviour is analyzed with regard to the degree of pre-reformi... [more]

10. LAPSE:2023.15765

Olive Mill Wastewater Valorization through Steam Reforming Using Multifunctional Reactors: Challenges of the Process Intensification

March 2, 2023 (v1)

Subject: Environment

Keywords: catalyst, H2 perm-selective membrane, olive mill wastewater valorization, sorbent, Steam Reforming

Olive oil mill wastewater (OMW) is a polluting stream derived from the production of olive oil and is a source of environmental pollution; this is relevant in many countries around the world, but particularly in all the Mediterranean region where major producers are located. In this effluent, several pollutants are present—namely, sugars, fatty acids, and polyphenols, among others. Nowadays, to reduce the pollutant load, several treatment techniques are applied, but these technologies have numerous cost and efficiency problems. For this reason, the steam reforming of the OMW (OMWSR) presents as a good alternative, because this process decreases the pollutant load of the OMW and simultaneously valorizes the waste with the production of green H2, which is consistent with the perspective of the circular economy. Currently, the OMWSR is an innovative treatment alternative in the scientific field and with high potential. In the last few years, some groups have studied the OMWSR and used inn... [more]

11. LAPSE:2023.14003

Exploiting Olive Mill Wastewater via Thermal Conversion of the Organic Matter into Gaseous Biofuel—A Case Study

March 1, 2023 (v1)

Subject: Energy Systems

Keywords: biofuel, cracking, membrane filtration, methanation, olive mill wastewater, Steam Reforming

Olive oil is one excellence of the Italian food industry: around 300 kt yr−1 are produced, creating roughly the same amount of olive mill wastewater (OMW) to be disposed of. The present work describes a process to exploit OMW by converting its organic compounds to valuable gaseous biofuel. A sample OMW was characterized (COD, TOC, solids, and polyphenols) and submitted to membrane filtration tests to concentrate the organic compounds. Based on the results of the experiments, a treatment process was outlined: the retentate streams from microfiltration and ultrafiltration steps were fed to a cracking and a steam reforming reactor, respectively; the obtained syngas streams were then mixed and sent to a methanation reactor. The process was simulated with Aspen Plus (AspenTech©) software, assessing operating conditions and streams compositions: the final biofuel is around 81 mol.% methane, 4 mol.% hydrogen, and 11 mol.% carbon dioxide. The permeate stream cannot be directly disposed of, but... [more]

12. LAPSE:2023.0089

Modern Technologies of Hydrogen Production

February 17, 2023 (v1)

Subject: Energy Systems

Keywords: biohydrogen, Biomass, hydrogen production, hydrogen storage, membrane catalysis, Steam Reforming, water electrolysis

Transitioning to energy-saving and renewable energy sources is impossible without accelerated development of hydrogen energy and hydrogen technologies. This review summarizes the state-of-the-art and recent advances of various hydrogen production processes, including but not limited to thermochemical and electrolytic processes. Their opportunities and limitations, operating conditions, and catalysts are discussed. Nowadays, most hydrogen is still produced by steam reforming of methane, its partial oxidation, or coal gasification. Considerable attention is also paid to natural gas pyrolysis. However, hydrogen produced using these technologies has a lot of impurities and needs additional purification. A series of technologies for hydrogen purification, including its filtration through palladium alloy membranes, and membrane catalysis, allowing hydrogen production and purification in one stage, are discussed. The main way to produce carbon-free hydrogen is water electrolysis using low-cos... [more]

13. LAPSE:2021.0235

Dynamic Modeling and Control of a Coupled Reforming/Combustor System for the Production of H2 via Hydrocarbon-Based Fuels

April 27, 2021 (v1)

Subject: Process Control

Keywords: C1–C4 feedstock, distributed control system, Dynamic Modelling, hydrogen production, PID control, Steam Reforming

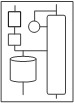

The present work aims to provide insights into the dynamic operation of a coupled reformer/combustion unit that can utilize a variety of saturated hydrocarbons (HCs) with 1−4 C atoms towards H2 production (along with CO2). Within this concept, a preselected HC-based feedstock enters a steam reforming reactor for the production of H2 via a series of catalytic reactions, whereas a sequential postprocessing unit (water gas shift reactor) is then utilized to increase H2 purity and minimize CO. The core unit of the overall system is the combustor that is coupled with the reformer reactor and continuously provides heat (a) for sustaining the prevailing endothermic reforming reactions and (b) for the process feed streams. The dynamic model as it is initially developed, consists of ordinary differential equations that capture the main physicochemical phenomena taking place at each subsystem (energy and mass balances) and is compared against available thermodynamic data (temperature and concent... [more]

14. LAPSE:2020.0364

Ultra-Pure Hydrogen via Co-Valorization of Olive Mill Wastewater and Bioethanol in Pd-Membrane Reactors

April 14, 2020 (v1)

Subject: Process Design

Keywords: bioethanol, Hydrogen, membrane reactor, olive mill wastewater, palladium membrane, Steam Reforming

Olive mill wastewater (OMW) presents high environmental impact due to the fact of its elevated organic load and toxicity, especially in Mediterranean countries. Its valorization for simultaneous pollutants degradation and green energy production is receiving great attention, mainly via steam reforming for hydrogen generation. Following previous works, the present research goes into detail about OMW valorization, particularly investigating for the first time the potential benefits of OMW−bioethanol mixtures co-reforming for ultra-pure hydrogen production in Pd-membrane reactors. In this manner, the typical large dilution of OMW and, hence, excess water can be used as a reactant for obtaining additional hydrogen from ethanol. Fresh OMW was previously conditioned by filtration and distillation processes, analyzing later the effect of pressure (1−5 bar), oxidizing conditions (N2 or air as carrier gas), gas hourly space velocity (150−1500 h−1), and alcohol concentration on the co-reforming... [more]

15. LAPSE:2018.0567

Production of Hydrogen by Methane Steam Reforming Coupled with Catalytic Combustion in Integrated Microchannel Reactors

September 21, 2018 (v1)

Subject: Reaction Engineering

Keywords: catalytic combustion, Computational Fluid Dynamics, hydrogen production, Process Intensification, process optimization, Steam Reforming, thermal management, thermally integrated microchannel reactors

This paper addresses the issues related to the rapid production of hydrogen from methane steam reforming by means of process intensification. Methane steam reforming coupled with catalytic combustion in thermally integrated microchannel reactors for the production of hydrogen was investigated numerically. The effect of the catalyst, flow arrangement, and reactor dimension was assessed to optimize the design of the system. The thermal interaction between reforming and combustion was investigated for the purpose of the rapid production of hydrogen. The importance of thermal management was discussed in detail, and a theoretical analysis was made on the transport phenomena during each of the reforming and combustion processes. The results indicated that the design of a thermally integrated system operated at millisecond contact times is feasible. The design benefits from the miniaturization of the reactors, but the improvement in catalyst performance is also required to ensure the rapid pr... [more]

16. LAPSE:2018.0168

Effects of Catalysts and Membranes on the Performance of Membrane Reactors in Steam Reforming of Ethanol at Moderate Temperature

July 30, 2018 (v1)

Subject: Process Design

Keywords: amorphous alloy membranes, Ethanol, membrane reactor, Steam Reforming

Steam reforming of ethanol in the membrane reactor using the Pd77Ag23 membrane was evaluated in Ni/CeO₂ and Co/CeO₂ at atmospheric pressure. At 673 K, the H₂ yield in the Pd77Ag23 membrane reactor over Co/CeO₂ was found to be higher than that over Ni/CeO₂, although the H₂ yield over Ni/CeO₂ exceeded that over Co/CeO₂ at 773 K. This difference was owing to their reaction mechanism. At 773 K, the effect of H₂ removal could be understood as the equilibrium shift. In contrast, the H₂ removal kinetically inhibited the reverse methane steam reforming at low temperature. Thus, the low methane-forming reaction rate of Co/CeO₂ was favorable at 673 K. The addition of a trace amount of Ru increased the H₂ yield effectively in the membrane reactor, indicating that a reverse H₂ spill over mechanism of Ru would enhance the kinetical effect of H₂ separation. Finally, the effect of membrane performance on the reactor performance by using amorphous alloy membranes with different compositions was evalua... [more]

17. LAPSE:2018.0127

Dynamic modeling of integrated mixed reforming and carbonless heat systems

June 12, 2018 (v1)

Subject: Modelling and Simulations

Keywords: Carbonless Heat, Dry Reforming, Dynamic Modelling, Integrated Systems, Steam Reforming, Syngas

In the previous study, a dynamic and two-dimensional model for a steam methane reforming process integrated with nuclear heat production was developed. It was shown that the integrated high temperature gas-cooled reactor (HTGR)/steam methane reforming (SMR) is an efficient process for applications such as hydrogen production. In this study, it is demonstrated that combining nuclear heat with the mix of steam and dry reforming process can be a promising option to achieve certain desired H2/CO ratios for Fischer-Tropsch or other downstream energy conversion processes. The model developed in the previous study is extended to the combined steam and dry reforming process. The resulting model was validated using reported experimental data at non-equilibrium and equilibrium conditions. The dynamic and steady state performance of the integrated mixed reforming of methane and nuclear heat system was studied and it was found that in addition to desired H2/CO ratios, higher methane conversion and... [more]

18. LAPSE:2018.0126

Biomass-Gas-and-Nuclear-To-Liquids Aspen Plus Simulations

December 7, 2018 (v2)

Subject: Modelling and Simulations

Keywords: Aspen Plus, Biomass, Dimethyl Ether, Fischer-Tropsch Synthesis, Natural Gas, Nuclear, Simulation, Steam Reforming

In this paper, several new processes are proposed which co-generate electricity and liquid fuels (such as diesel, gasoline, or dimethyl ether) from biomass, natural gas and heat from a high temperature gas-cooled reactor. This carbonless heat provides the required energy to drive an endothermic steam methane reforming process, which yields H2-rich syngas (H2/CO>6) with lower greenhouse gas emissions than traditional steam methane reforming processes. Since downstream Fischer-Tropsch, methanol, or dimethyl ether synthesis processes require an H2/CO ratio of around 2, biomass gasification is integrated into the process. Biomass-derived syngas is sufficiently H2-lean such that blending it with the steam methane reforming derived syngas yields a syngas of the appropriate H2/CO ratio of around 2. In a prior work, we also demonstrated that integrating carbonless heat with combined steam and CO2 reforming of methane is a promising option to produce a syngas with proper H2/CO ratio for Fischer... [more]