Browse

Recent Submissions

New records verified within the last 30 days

Aspen Plus and Aspen HYSYS Simulations for: Comparative environmental techno-economic assessments (eTEAs) of onboard amine-based carbon capture and boil-off gas handling systems on LCO2 carriers

November 5, 2025 (v1)

Subject: Modelling and Simulations

Keywords: Absorption, Boil off gas, Environmental Techno-Economic Assessment, LCO2 carrier, MEA, OCCS, Onboard carbon capture

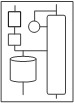

The continuous increase in greenhouse gas emissions and the strengthening of environmental regulations have brought Carbon Capture, Utilization, and Storage (CCUS) technology into focus. Most liquefied carbon dioxide carriers (LCO2Cs) employ liquefied natural gas (LNG) propulsion, but they still emit significant greenhouse gases, highlighting the need for further reduction. While boil-off gas (BOG) handling is essential for long-distance LCO2C operations, no studies have examined onboard carbon capture systems (OCCS) integrated with BOG handling systems. This study evaluates five operational cases—BOG re-liquefaction (RLIQ), OCCS, purge gas recapture, and their combinations—to assess the greenhouse gas reduction and economic feasibility of LCO2Cs. Although standalone RLIQ and OCCS showed similar reduction rates (29% and 30%), the avoidance cost of OCCS alone was more than two times higher. Integrating BOG RLIQ, OCCS, and purge recirculation achieved up to 69% well-to-wake emission redu... [more]