Browse

Keywords

Records with Keyword: Semicontinuous Distillation

On the application of shooting method for determining semicontinuous distillation limit cycles

August 17, 2020 (v1)

Subject: Numerical Methods and Statistics

Keywords: Hybrid Dynamical System, Limit Cycle, Optimization, Process Design, Semicontinuous Distillation

Semicontinuous distillation is a new separation technology for distilling multicomponent mixtures.

This process was designed using design methodologies with heuristic components that evolved

over twenty years. However, the fundamental philosophy of these design methodologies, which

involves guessing, checking and then using a black-box optimization procedure to find the values

of the design variables to meet some performance criteria, has not changed. Mainly, to address the

problem of having a heuristic simulation termination criterion in the black-box optimization phase,

the single shooting method for semicontinuous distillation design was proposed in this study. We

envision that this is a first step in the transformation of the semicontinuous distillation design

process for obtaining optimal designs. We demonstrate the application of this method using two

case studies, which involve the separation of hexane, heptane and octane.

This process was designed using design methodologies with heuristic components that evolved

over twenty years. However, the fundamental philosophy of these design methodologies, which

involves guessing, checking and then using a black-box optimization procedure to find the values

of the design variables to meet some performance criteria, has not changed. Mainly, to address the

problem of having a heuristic simulation termination criterion in the black-box optimization phase,

the single shooting method for semicontinuous distillation design was proposed in this study. We

envision that this is a first step in the transformation of the semicontinuous distillation design

process for obtaining optimal designs. We demonstrate the application of this method using two

case studies, which involve the separation of hexane, heptane and octane.

Single Shooting Method for Semicontinuous Distillation

January 6, 2020 (v1)

Subject: Process Design

Keywords: Hybrid Dynamical System, Process Design, Semicontinuous Distillation, Single Shooting Method

Semicontinuous distillation is a new separation technology for distilling multicomponent mixtures. This process was designed using design methodologies with heuristic components that evolved over twenty years. However, the fundamental philosophy of these design methodologies, which involves guessing, checking and then using a black-box optimization procedure to find the values of the design variables to meet some performance criteria, has not changed. Mainly, to address the problem of having a heuristic simulation termination criterion in the black-box optimization phase, the single shooting method for semicontinuous distillation design was proposed in this study. We envision that this is a first step in the transformation of the semicontinuous distillation design process for obtaining optimal designs. We demonstrate the application of this method using two case studies, which involve the separation of hexane, heptane and octane.

Single Shooting Method for Semicontinuous Distillation Design

November 13, 2019 (v2)

Subject: Process Design

Keywords: Boundary Value Problem, CasADi, Cyclic Steady State, Semicontinuous Distillation, Single Shooting

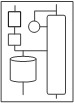

Ternary separation using the process of semicontinuous distillation was proposed to be carried out in a single distillation column and a process vessel, which is called the middle vessel [1]. During the process of separation, inlet and outlet material streams of the middle vessel are either operational or non-operational based on its state. With the help of these state-dependent discrete actions, periodic feed charges and the intermediate-boiling product discharges are carried out in the middle vessel, while the low and high volatile components are removed continuously from the column. This periodic process is thus modelled mathematically as a limit-cycle oscillating hybrid system [2] for design purposes. The semicontinuous distillation process design involves estimating equipment sizes, controller tuning parameters, and column design parameters which are all time-invariant parameters of the oscillating hybrid system. These system parameters are chosen to operate the process in a hydra... [more]

Finding better limit cycles of semicontinuous distillation. Part 1: Back-stepping design Methodology

July 9, 2019 (v1)

Subject: Process Design

Keywords: Hybrid dynamic system, Limit Cycle, Particle Swarm Optimization, Process Design, Semicontinuous Distillation

Semicontinuous ternary zeotropic distillation is a periodic process that is carried out

in a single distillation column and a tightly integrated external middle vessel. In the

state-of-the-art design procedure of this process, a continuous distillation process that

separates the top and bottoms products to the desired purity is used to generate an arbitrary

initial state for simulating the dynamics of the semicontinuous distillation process.

Although this method is useful in estimating the limit cycle, it was later found that the

operation of the process in this limit cycle was economically sub-optimal. In this study,

a new algorithmic design procedure, called the back-stepping design methodology, is

proposed to find better limit cycles for zeotropic ternary semicontinuous distillation

using the aspenONE Engineering suite. The proposed methodology was applied to two

different case studies using feed mixtures with different chemical components. A comparison

with the current d... [more]

in a single distillation column and a tightly integrated external middle vessel. In the

state-of-the-art design procedure of this process, a continuous distillation process that

separates the top and bottoms products to the desired purity is used to generate an arbitrary

initial state for simulating the dynamics of the semicontinuous distillation process.

Although this method is useful in estimating the limit cycle, it was later found that the

operation of the process in this limit cycle was economically sub-optimal. In this study,

a new algorithmic design procedure, called the back-stepping design methodology, is

proposed to find better limit cycles for zeotropic ternary semicontinuous distillation

using the aspenONE Engineering suite. The proposed methodology was applied to two

different case studies using feed mixtures with different chemical components. A comparison

with the current d... [more]

Finding better limit cycles of semicontinuous distillation

March 22, 2019 (v1)

Subject: Process Design

There are three different ways of operating the distillation process based on production requirements and operational flexibility. Semicontinuous distillation of multicomponent mixtures is a cost-effective technology in the intermediate production range when compared with traditional batch and continuous distillation processes. The process, which has both continuous and discrete dynamics, operates in a limit cycle (an isolated periodic orbit). Design of this process entails finding the system’s time-invariant parameters, for example, equipment design parameters, reflux rate etc., to operate in a limit cycle having acceptable performance. In semicontinuous distillation studies, the performance metric chosen is the separation cost, which is defined as the total annualized cost-per-production. The state-of-the-art design procedure involves determining an initial state for estimating the limit cycle through the dynamic simulation of the process and is found to be effective. However, it lac... [more]

Side Stream Control in Semicontinuous Distillation

October 18, 2018 (v1)

Subject: Process Control

Keywords: dynamic optimization, dynamical system analysis, Semicontinuous Distillation, side stream control

The idea to reduce cycle time (𝑇), by controlling the side stream flow rate using a feedforward control model -- the ideal side draw recovery arrangement (ISR) -- was standard in most semicontinuous distillation studies. However, its effect, particularly on ‘𝑇’ and more broadly on the system dynamics, was not clearly understood. In the current study, we compare the performance of using a modified form of ISR model with the status quo, based on the criteria, 𝑇 and separating cost (SC) on different case studies. Results show that the modified control model performed better with a 10-20% reduction in SC while maintaining product purities. Furthermore, the side stream flow rate trajectory that minimizes SC was found by using dynamic optimization and it did not differ a lot from the trajectory generated by the modified control model. The improvement in SC was at most 2%.

Space-constrained purification of dimethyl ether through process intensification using semicontinuous dividing wall columns

June 12, 2018 (v1)

Subject: Process Design

Keywords: Aspen Plus, Dimethyl Ether, Dividing wall column, Mobile Plant, Plant-on-a-truck, Process Intensification, Semicontinuous Distillation, Simulation

In this work, a distillation system is designed to purify dimethyl ether (DME) from its reaction by-products in the conversion of flare gas into a useful energy product. The distillation equipment has a size constraint for easy transportation, making process intensification the best strategy to efficiently separate the mixture. The process intensification distillation techniques explored include the dividing wall column (DWC) and a novel semicontinuous dividing wall column (S-DWC). The DWC and the S-DWC both purify DME to fuel grade purity along with producing high purity waste streams. An economic comparison is made between the two systems. The DWC is a cheaper method of producing DME however the purity of methanol, a reaction intermediate, is not as high as the S-DWC. Overall, this research shows that it is possible to purify DME and its reaction by-products in a 40-foot distillation column at a cost that is competitive with Diesel.